Many already know that I have a weakness for all kinds of power supplies, here is a two-in-one review. This time there will be an overview of the radio designer, which allows you to assemble the basis for a laboratory power supply and a variant of its real implementation.

I warn you, there will be a lot of photos and text, so stock up on coffee :)

To begin with, I will explain a little what it is and why.

Almost all radio amateurs use such a thing as a laboratory power supply in their work. Whether it's complex with software control or very simple on the LM317, it still does almost the same thing, powering different loads in the process of working with them.

Laboratory power supplies are divided into three main types.

With impulse stabilization.

with linear stabilization

Hybrid.

The former incorporate a pulsed controlled power supply, or simply a pulsed power supply with a PWM buck converter. I have already reviewed several options for these power supplies. , .

Advantages - high power with small dimensions, excellent efficiency.

Disadvantages - RF ripple, the presence of capacitive capacitors at the output

The latter do not have any PWM converters on board, all adjustment is carried out in a linear way, where the excess energy is dissipated simply on the regulating element.

Pros - Virtually no ripple, no need for output capacitors (almost).

Cons - efficiency, weight, size.

The third ones are a combination of either the first type with the second, then the linear stabilizer is powered by a slave PWM buck converter (the voltage at the output of the PWM converter is always maintained at a level slightly higher than the output, the rest is regulated by a transistor operating in linear mode.

Either this is a linear power supply, but the transformer has several windings that switch as needed, thereby reducing losses on the regulating element.

This scheme has only one minus, the complexity, it is higher than the first two options.

Today we will talk about the second type of power supply, with a regulating element operating in linear mode. But consider this power supply using the example of a designer, it seems to me that this should be even more interesting. Indeed, in my opinion, this is a good start for a novice radio amateur, to assemble one of the main instruments for himself.

Well, or as they say, the right power supply should be heavy :)

This review is more aimed at beginners, experienced comrades are unlikely to find anything useful in it.

I ordered a constructor for review, which allows you to assemble the main part of the laboratory power supply.

The main characteristics are as follows (from the ones declared by the store):

Input voltage - 24 Volts AC

The output voltage is adjustable - 0-30 Volts DC.

Output current adjustable - 2mA - 3A

Output voltage ripple - 0.01%

The dimensions of the printed board are 80x80mm.

A little about the packaging.

The designer came in a regular plastic bag, wrapped in a soft material.

Inside, in an anti-static bag with a latch, were all the necessary components, including the circuit board.

Inside, everything was a mound, but nothing was damaged, the printed circuit board partially protected the radio components.

I will not list everything that is included in the kit, it's easier to do it later in the course of the review, I can only say that I had enough of everything, even something left.

A little about the printed circuit board.

The quality is excellent, the circuit is not included, but all the ratings on the board are indicated.

The board is double-sided, covered with a protective mask.

Board coating, tinning, and the very quality of the textolite is excellent.

I only managed to tear off a patch from the seal in one place, and then, after I tried to solder a non-native part (for some reason, it will be further).

In my opinion, the most for a novice radio amateur, it will be hard to spoil.

Before installation, I drew a diagram of this power supply.

The scheme is quite thoughtful, although not without flaws, but I will talk about them in the process.

Several main nodes are visible in the diagram, I separated them with a color.

Green - voltage regulation and stabilization unit

Red - current adjustment and stabilization unit

Violet - node indicating the transition to the current stabilization mode

Blue - reference voltage source.

Separately, there are:

1. Input diode bridge and filter capacitor

2. Power control unit on transistors VT1 and VT2.

3. Protection on the transistor VT3, turning off the output until the power of the operational amplifiers is normal

4. Fan power stabilizer, built on the 7824 chip.

5. R16, R19, C6, C7, VD3, VD4, VD5, unit for forming the negative pole of the power supply of operational amplifiers. Due to the presence of this node, the PSU will not work simply from direct current, it is the AC input from the transformer that is needed.

6. C9 output capacitor, VD9, output protection diode.

First, I will describe the advantages and disadvantages of the circuit design.

Pros -

I am glad that there is a stabilizer to power the fan, but the fan is needed for 24 volts.

I am very pleased with the presence of a negative polarity power supply, this greatly improves the operation of the PSU at currents and voltages close to zero.

In view of the presence of a source of negative polarity, protection was introduced into the circuit, until this voltage is present, the PSU output will be turned off.

The PSU contains a reference voltage source of 5.1 Volts, which not only allowed to correctly regulate the output voltage and current (with such a scheme, the voltage and current are regulated from zero to the maximum linearly, without “humps” and “dips” at extreme values), but also makes it possible to control external power supply, just change the control voltage.

The output capacitor is very small, which allows you to safely test the LEDs, there will be no inrush current until the output capacitor is discharged and the PSU enters current stabilization mode.

The output diode is necessary to protect the PSU from applying reverse polarity voltage to its output. True, the diode is too weak, it is better to replace it with another one.

Minuses.

The current sense shunt has too high a resistance, because of this, when operating with a load current of 3 Amperes, about 4.5 watts of heat is generated on it. The resistor is rated at 5 watts, but the heating is very large.

The input diode bridge is made up of 3 Amp diodes. For good, diodes should be at least 5 Amperes, since the current through the diodes in such a circuit is 1.4 of the output, respectively, in operation, the current through them can be 4.2 Amperes, and the diodes themselves are designed for 3 Amperes. The situation is only facilitated by the fact that the pairs of diodes in the bridge work alternately, but still this is not entirely correct.

The big disadvantage is that Chinese engineers, when selecting operational amplifiers, chose an op-amp with a maximum voltage of 36 Volts, but did not think that there was a negative voltage source in the circuit and the input voltage in this embodiment was limited to 31 Volts (36-5 = 31 ). With an input of 24 volts AC, the constant will be about 32-33 volts.

Those. The OU will operate in an extreme mode (36 is the maximum, standard 30).

I will talk about the pros and cons, as well as about the upgrade later, but now I will move on to the actual assembly.

First, let's lay out everything that is included in the kit. This will facilitate the assembly, and it will simply be more clearly visible what has already been installed and what is left.

I recommend starting the assembly with the lowest elements, because if you set high ones first, then it will be inconvenient to set low ones later.

It is also better to start by installing those components that are more of the same.

I'll start with resistors, and these will be 10 kΩ resistors.

The resistors are of high quality and have an accuracy of 1%.

A few words about resistors. Resistors are color coded. To many, this may seem inconvenient. In fact, this is better than alphanumeric marking, since the marking is visible in any position of the resistor.

Do not be afraid of color marking, at the initial stage you can use it, and over time it will be possible to determine it already without it.

To understand and conveniently work with such components, you just need to remember two things that will be useful to a novice radio amateur in life.

1. Ten basic marking colors

2. Ratings of the series, they are not very useful when working with precise resistors of the E48 and E96 series, but such resistors are much less common.

Any radio amateur with experience will list them simply from memory.

1, 1.1, 1.2, 1.3, 1.5, 1.6, 1.8, 2, 2.2, 2.4, 2.7, 3, 3.3, 3.6, 3.9, 4.3, 4.7, 5.1, 5.6, 6.2, 6.8, 7.5, 8.2, 9.1.

All other denominations are the multiplication of these by 10, 100, etc. For example 22k, 360k, 39ohm.

What does this information give?

And she gives that if the resistor of the E24 series, then for example a combination of colors -

Blue + green + yellow in it is impossible.

Blue - 6

Green - 5

Yellow - x10000

those. according to calculations, it turns out 650k, but there is no such value in the E24 series, there is either 620 or 680, which means that either the color is recognized incorrectly, or the color is changed, or the resistor is not the E24 series, but the latter is rare.

Okay, enough theory, let's move on.

Before mounting, I shape the resistor leads, usually with tweezers, but some people use a small homemade device for this.

We are not in a hurry to throw away the cuttings of the conclusions, it happens that they can be useful for jumpers.

Having set the main amount, I reached single resistors.

It can be harder here, you will have to deal with the denominations more often.

I don’t solder the components right away, but I just bite and bend the conclusions, and I bite it first, and then bend it.

This is done very easily, the board is held in the left hand (if you are right-handed), at the same time the installed component is pressed.

There are side cutters in the right hand, we bite the conclusions (sometimes even several components at once), and immediately bend the conclusions with the side edge of the side cutters.

This is all done very quickly, after a while already on automatism.

So we got to the last small resistor, the value of the required and the one that remains is the same, already not bad :)

Having installed the resistors, we move on to diodes and zener diodes.

There are four small diodes here, these are the popular 4148, there are two 5.1 Volt zener diodes each, so it is very difficult to get confused.

They also form conclusions.

On the board, the cathode is indicated by a strip, as well as on diodes and zener diodes.

Although the board has a protective mask, I still recommend bending the leads so that they do not fall on adjacent tracks, in the photo the diode lead is bent away from the track.

The zener diodes on the board are also marked as markings on them - 5V1.

There are not very many ceramic capacitors in the circuit, but their marking can confuse a novice radio amateur. By the way, it also obeys the E24 series.

The first two digits are the value in picofarads.

The third digit is the number of zeros to be added to the face value

Those. for example 331 = 330pF

101 - 100pF

104 - 100000pF or 100nF or 0.1uF

224 - 220000pF or 220nF or 0.22uF

The main number of passive elements has been established.

After that, we proceed to the installation of operational amplifiers.

I would probably recommend buying sockets for them, but I soldered them as is.

On the board, as well as on the microcircuit itself, the first output is marked.

The rest of the pins are counted counterclockwise.

The photo shows a place for an operational amplifier and how it should be placed.

For microcircuits, I do not bend all the conclusions, but only a couple, usually these are the extreme conclusions diagonally.

Well, it's better to bite them so that they stick out about 1mm above the board.

Everything, now you can go to soldering.

I use the most common soldering iron with temperature control, but a regular soldering iron with a power of about 25-30 watts is quite sufficient.

Solder diameter 1mm with flux. I specifically do not indicate the brand of solder, since there is non-native solder on the coil (native coils weighing 1Kg), and few people will know its name.

As I wrote above, the board is of high quality, it is soldered very easily, I did not use any fluxes, only what is in the solder is enough, you just need to remember to shake off the excess flux from the tip sometimes.

Here I took a photo with an example of good soldering and not very good.

A good solder should look like a small droplet enveloping the lead.

But in the photo there are a couple of places where the solder is clearly not enough. This will happen on a double-sided board with metallization (where the solder also flows inside the hole), but this cannot be done on a single-sided board, over time such soldering can “fall off”.

The conclusions of the transistors must also be pre-molded, this must be done in such a way that the conclusion is not deformed near the base of the case (the elders will remember the legendary KT315, in which the conclusions liked to break off).

I shape powerful components a little differently. Molding is done so that the component is above the board, in which case less heat will transfer to the board and will not destroy it.

This is what the molded powerful resistors on the board look like.

All components were soldered only from the bottom, the solder that you see on the top of the board penetrated through the hole due to the capillary effect. It is advisable to solder in such a way that the solder penetrates a little to the top, this will increase the reliability of the soldering, and in the case of heavy components, their better stability.

If before that I molded the conclusions of the components with tweezers, then for the diodes I will already need small pliers with narrow jaws.

The conclusions are formed in much the same way as for resistors.

But there are differences when installing.

If for components with thin leads, installation first occurs, then biting, then for diodes the opposite is true. You simply won’t bend such a conclusion after biting, so first we bend the conclusion, then we bite off the excess.

The power unit is assembled using two transistors connected according to the Darlington circuit.

One of the transistors is mounted on a small heatsink, preferably through thermal paste.

There were four M3 screws in the kit, one goes here.

A couple of photos of an almost soldered board. I will not describe the installation of terminal blocks and other components, it is intuitive, and you can see it from the photo.

By the way, about the terminal blocks, there are terminal blocks on the board for connecting the input, output, fan power.

I have not washed the board yet, although I often do this at this stage.

This is due to the fact that there will be a small part of the refinement.

After the main assembly step, we are left with the following components.

Power transistor

Two variable resistors

Two board connectors

Two connectors with wires, by the way, the wires are very soft, but of a small cross section.

Three screws.

Initially, the manufacturer planned to place variable resistors on the board itself, but they are placed so inconveniently that I didn’t even solder them and showed them just for example.

They stand very close and it will be extremely inconvenient to regulate, although it is real.

But thank you for not forgetting to give wires with connectors in the kit, it's much more convenient.

In this form, the resistors can be placed on the front panel of the device, and the board can be installed in a convenient place.

Along the way, soldered a powerful transistor. This is an ordinary bipolar transistor, but with a maximum power dissipation of up to 100 watts (of course, when installed on a radiator).

There are three screws left, I didn’t understand where to even apply them, if at the corners of the board, then four are needed, if you attach a powerful transistor, then they are short, in general, a mystery.

You can power the board from any transformer with an output voltage of up to 22 Volts (24 is stated in the specifications, but I explained above why such a voltage cannot be used).

I decided to use a transformer for the Romantik amplifier that I had for a long time. Why for, and not from, but because he has not yet stood anywhere :)

This transformer has two output power windings of 21 Volts, two auxiliary windings of 16 Volts and a shielding winding.

The voltage is indicated for the input 220, but since we now have a standard of 230, the output voltages will also be slightly higher.

The calculated power of the transformer is about 100 watts.

I paralleled the output power windings to get more current. Of course, it was possible to use a rectification circuit with two diodes, but it won’t be better with it, so I left it as it is.

For those who do not know how to determine the power of a transformer, I made a short video.

First trial run. I installed a small radiator on the transistor, but even in this form there was quite a lot of heating, since the PSU is linear.

Adjustment of current and voltage occurs without problems, everything worked right away, so I can already fully recommend this designer.

The first photo is voltage stabilization, the second is current.

To begin with, I checked what the transformer outputs after rectification, as this determines the maximum output voltage.

I got about 25 volts, not a lot. The capacity of the filter capacitor is 3300uF, I would advise you to increase it, but even in this form the device is quite efficient.

Since for further verification it was already necessary to use a normal radiator, I proceeded to assemble the entire future structure, since the installation of the radiator depended on the intended design.

I decided to use the Igloo7200 radiator that I have. According to the manufacturer, such a radiator is capable of dissipating up to 90 watts of heat.

The device will use a Z2A case based on the idea of Polish production, the price is about 3 dollars.

Initially, I wanted to move away from the case that bored my readers, in which I collect all sorts of electronic things.

To do this, I chose a slightly smaller case and bought a fan with a mesh for it, but I couldn’t put all the stuffing into it and a second case was purchased and, accordingly, a second fan.

In both cases, I bought Sunon fans, I really like the products of this company, and in both cases, 24 Volt fans were bought.

This is how I planned to install a radiator, a board and a transformer. There is even a little space left for expanding the filling.

There was no way to put the fan inside, so it was decided to place it outside.

We mark the mounting holes, cut the threads, screw them for fitting.

Since the selected case has an internal height of 80mm, and the board is also of this size, I fixed the heatsink so that the board is symmetrical with respect to the heatsink.

The conclusions of a powerful transistor also need to be molded a little so that they do not deform when the transistor is pressed against the radiator.

A small digression.

For some reason, the manufacturer conceived a place to install a rather small radiator, because of this, when installing a normal one, it turns out that the fan power regulator and the connector for connecting it interfere.

I had to solder them out, and seal the place where they were with tape so that there was no connection with the radiator, since there was voltage on it.

I cut off the extra tape on the reverse side, otherwise it turned out somehow completely sloppy, we will do it according to Feng Shui :)

This is how the printed circuit board looks like with the heatsink finally installed, the transistor is installed through thermal paste, and it is better to use good thermal paste, since the transistor dissipates power comparable to a powerful processor, i.e. about 90 watts.

At the same time, I immediately made a hole for installing the fan speed controller board, which in the end still had to be re-drilled :)

To set zero, I unscrewed both regulators to the extreme left position, disconnected the load and set the output to zero. Now the output voltage will be adjusted from zero.

A few tests follow.

I checked the accuracy of maintaining the output voltage.

Idling, voltage 10.00 Volts

1. Load current 1 Amp, voltage 10.00 Volts

2. Load current 2 Amperes, voltage 9.99 Volts

3. Load current 3 Amperes, voltage 9.98 Volts.

4. Load current 3.97 Amps, voltage 9.97 Volts.

The characteristics are very good, if desired, they can be improved a little more by changing the connection point of the voltage feedback resistors, but as for me, it’s enough.

I also checked the ripple level, the test took place at a current of 3 Amperes and an output voltage of 10 Volts

The ripple level was about 15mV, which is very good, though I thought that in fact the ripples shown in the screenshot were more likely to climb from the electronic load than from the PSU itself.

After that, I proceeded to assemble the device itself as a whole.

I started by installing a radiator with a power supply board.

To do this, I marked out the installation location of the fan and the power connector.

The hole was marked not quite round, with small "cuts" at the top and bottom, they are needed to increase the strength of the back panel after cutting the hole.

The biggest difficulty is usually the holes of complex shape, for example, under the power connector.

A large hole is cut from a large pile of small ones :)

Drill + drill with a diameter of 1mm sometimes work wonders.

Drill holes, lots of holes. It may seem that it is long and tedious. No, on the contrary, it is very fast, the complete drilling of the panel takes about 3 minutes.

After that, I usually put the drill a little more, for example 1.2-1.3mm and go through it like a cutter, it turns out such a cut:

After that, we take a small knife in our hands and clean the resulting holes, at the same time we cut the plastic a little if the hole turned out to be a little smaller. The plastic is quite soft, so it's comfortable to work with.

The last stage of preparation is drilling mounting holes, we can say that the main work on the back panel is over.

We install a heatsink with a board and a fan, try on the result, if necessary, “finish it with a file”.

Almost at the very beginning, I mentioned refinement.

I will work on it a little.

To begin with, I decided to replace the native diodes in the input diode bridge with Schottky diodes, I bought four pieces of 31DQ06 for this. and then I repeated the mistake of the board developers, buying by inertia diodes for the same current, but I had to have a larger one. But all the same, the heating of the diodes will be less, since the drop on Schottky diodes is less than on conventional ones.

Secondly, I decided to replace the shunt. I was not satisfied not only with the fact that it heats up like an iron, but also with the fact that about 1.5 Volts falls on it, which can be put into action (in the sense of a load). For this, I took two domestic 0.27 Ohm 1% resistors (this will also improve stability). Why the developers didn’t do this is not clear, the price of the solution is absolutely the same as in the version with a native 0.47 Ohm resistor.

Well, rather as an addition, I decided to replace the native filter capacitor 3300uF with a better and more capacious Capxon 10000uF ...

This is what the resulting design looks like with the replaced components and the fan thermal control board installed.

It turned out a little collective farm, and besides, I accidentally ripped off one patch on the board when installing powerful resistors. In general, it was possible to safely use less powerful resistors, for example, one 2-watt resistor, I just didn’t have this available.

A few components have also been added to the bottom.

3.9k resistor, parallel to the extreme contacts of the connector for connecting the current regulation resistor. It is needed to reduce the adjustment voltage, since the voltage on the shunt is now different.

A pair of 0.22uF capacitors, one in parallel with the output from the current control resistor, to reduce interference, the second is just at the output of the power supply, it is not really needed, I just accidentally took out a pair at once and decided to use both.

The entire power part is connected, a board with a diode bridge and a capacitor is installed on the transformer to power the voltage indicator.

By and large, this board is optional in the current version, but I didn’t raise my hand to power the indicator from its limiting 30 Volts and I decided to use an additional 16 Volt winding.

The following components were used to organize the front panel:

Load terminals

Pair of metal handles

Power switch

Red light filter, declared as a light filter for KM35 housings

To indicate current and voltage, I decided to use the board that I had left after writing one of the reviews. But I was not satisfied with small indicators and therefore larger numbers with a height of 14mm were bought, and a printed circuit board was made for them.

In general, this solution is temporary, but I even wanted to temporarily do it carefully.

Several stages of preparation of the front panel.

1. Draw the layout of the front panel in full size (I use the usual Sprint Layout). The advantage of using identical enclosures is that it is very easy to prepare a new panel, since the required dimensions are already known.

We apply the printout to the front panel and drill marking holes with a diameter of 1mm in the corners of the square / rectangular holes. With the same drill we drill the centers of the remaining holes.

2. According to the resulting holes, we mark the places of the cut. Change the tool to a thin disc cutter.

3. We cut straight lines, clearly in size in front, a little more in the back, so that the cut is as full as possible.

4. We break out the cut pieces of plastic. I usually don't throw them away as they might still come in handy.

Similarly to the preparation of the back panel, we process the resulting holes with a knife.

I recommend drilling large diameter holes, it does not "bite" the plastic.

We try on what we got, if necessary, modify it with a needle file.

I had to slightly widen the hole for the switch.

As I wrote above, for indication, I decided to use the board left over from one of the previous reviews. In general, this is a very bad solution, but more than suitable for a temporary option, I will explain why later.

We solder the indicators and connectors from the board, call the old indicators and the new ones.

I painted for myself the pinout of both indicators so as not to get confused.

In the native version, four-digit indicators were used, I used three-digit ones. because I no longer fit into the window. But since the fourth digit is needed only to display the letter A or U, their loss is not critical.

I placed the LED for indicating the current limiting mode between the indicators.

I prepare everything necessary, from the old board I solder a 50mΩ resistor, which will be used as before, as a current-measuring shunt.

This shunt is the problem. The fact is that in this version I will have a voltage drop at the output of 50mV for every 1 ampere of load current.

There are two ways to get rid of this problem, use two separate meters, for current and voltage, while powering the voltmeter from a separate power source.

The second way is to install a shunt in the positive pole of the PSU. Both options did not suit me as a temporary solution, so I decided to step on the throat of my perfectionism and make a simplified version, but far from the best.

For the construction, I used the mounting posts left over from the DC-DC converter board.

With them, I got a very convenient design, the indicator board is attached to the ampervoltmeter board, which in turn is attached to the power terminal board.

It turned out even better than I expected :)

I also placed a current-measuring shunt on the power terminal board.

The resulting front panel design.

And then I remembered that I forgot to install a more powerful protective diode. I had to solder it later. I used a diode left after replacing the diodes in the input bridge of the board.

Of course, for good it would be necessary to add a fuse, but this is no longer in this version.

But I decided to put the current and voltage adjustment resistors better than those suggested by the manufacturer.

The native ones are quite high-quality, and have a smooth run, but these are ordinary resistors, and as for me, the laboratory power supply should be able to more accurately adjust the output voltage and current.

Even when I was thinking of ordering a power supply board, I saw them in the store and ordered them for a review, especially since they had the same denomination.

In general, I usually use other resistors for such purposes, they combine two resistors inside themselves at once, for coarse and smooth adjustment, but recently I can’t find them on sale.

Maybe someone knows their imported counterparts?

The resistors are quite high quality, the angle of rotation is 3600 degrees, or in simple terms - 10 full turns, which provides a tuning of 3 Volts or 0.3 Amperes per 1 turn.

With such resistors, the adjustment accuracy is about 11 times more accurate than with conventional ones.

New resistors in comparison with relatives, the size is certainly impressive.

Along the way, I shortened the wires to the resistors a little, this should improve noise immunity.

I packed everything in the case, in principle, there was even a little space left, there is room to grow :)

I connected the shielding winding to the grounding conductor of the connector, the additional power board is located directly on the transformer terminals, this is of course not very neat, but I have not yet come up with another option.

Check after assembly. Everything started up almost the first time, I accidentally mixed up two digits on the indicator and for a long time could not understand what was wrong with the adjustment, after switching everything became as it should.

The last stage is gluing the light filter, installing handles and assembling the body.

The light filter has a thinning around the perimeter, the main part is recessed into the housing window, and the thinner part is glued with double-sided tape.

The handles were originally designed for a shaft diameter of 6.3mm (if I don’t confuse), the new resistors have a thinner shaft, I had to put a couple of layers of heat shrink on the shaft.

I decided not to design the front panel in any way yet, and there are two reasons for this:

1. Management is so intuitive that there is no special meaning in the inscriptions yet.

2. I plan to modify this power supply, so changes in the design of the front panel are possible.

A couple of photos of the resulting design.

Front view:

Back view.

Attentive readers must have noticed that the fan is positioned in such a way that it blows hot air out of the case, and does not force cold air between the radiator fins.

I decided to do this because the heatsink is slightly smaller than the case, and so that hot air does not get inside, I put the fan in reverse. This, of course, significantly reduces the efficiency of heat dissipation, but it allows you to slightly ventilate the space inside the PSU.

Additionally, I would recommend making a few holes from the bottom of the bottom half of the case, but this is more of an addition.

After all the alterations, I got a current slightly less than in the original version, and amounted to about 3.35 Amperes.

And so, I will try to paint the pros and cons of this board.

pros

Excellent workmanship.

Almost correct circuitry of the device.

A complete set of parts for assembling the power supply stabilizer board

Good for beginner radio amateurs.

In a minimal form, only a transformer and a radiator are additionally required, in a more advanced form, an ampervoltmeter is also required.

Fully functional after assembly, although with some nuances.

The absence of capacitive capacitors at the PSU output, it is safe when checking LEDs, etc.

Minuses

The type of operational amplifiers is incorrectly selected, because of this, the input voltage range should be limited to 22 Volts.

Not a very suitable current measurement resistor value. It works in its normal thermal mode, but it is better to replace it, since the heating is very large and can harm the surrounding components.

The input diode bridge is working at maximum, it is better to replace the diodes with more powerful ones

My opinion. During the assembly process, I got the impression that the circuit was developed by two different people, one applied the correct principle of adjustment, reference voltage source, negative voltage source, protection. The second one incorrectly selected a shunt, operational amplifiers and a diode bridge for this case.

I really liked the circuitry of the device, and in the refinement section, I first wanted to replace the operational amplifiers, I even bought microcircuits with a maximum operating voltage of 40 volts, but then I changed my mind about modifying it. but otherwise the solution is quite correct, the adjustment is smooth and linear. Of course there is heating, without it nowhere. In general, as for me, for a beginner radio amateur this is a very good and useful constructor.

Surely there will be people who will write that it’s easier to buy ready-made, but I think that it’s more interesting to assemble it yourself (probably this is the most important thing) and more useful. In addition, many quite calmly at home have both a transformer and a heatsink from an old processor, and some kind of box.

Already in the process of writing a review, I had an even stronger feeling that this review would be the beginning of a series of reviews dedicated to a linear power supply, there are thoughts for improvement -

1. Translation of the indication and control circuit into a digital version, possibly with a connection to a computer

2. Replacing operational amplifiers with high-voltage ones (I don’t know which ones yet)

3. After replacing the op amp, I want to make two automatically switching stages and expand the output voltage range.

4. Change the principle of current measurement in the display device so that there is no voltage drop under load.

5. Add the ability to turn off the output voltage with a button.

That's probably all. Maybe I'll remember something and add, but more I'm waiting for comments with questions.

Also, I plan to devote a few more reviews to designers for beginner radio amateurs, maybe someone will have suggestions about certain designers.

Not for the faint of heart

At first I didn’t want to show it, but then I decided to take a photo anyway.

On the left is the power supply that I used for many years before.

This is a simple linear PSU with an output of 1-1.2 Amperes at a voltage of up to 25 Volts.

So I wanted to replace it with something more powerful and correct.

The product was provided for writing a review by the store. The review is published in accordance with clause 18 of the Site Rules.

I plan to buy +249 Add to favorites Liked the review +160 +378

I have a regulated power supply. Only voltage is regulated, respectively, there is no current regulation. For some purposes, it is enough. I decided to assemble a unit with current and voltage regulation. Laboratory power supply, hereinafter referred to as LBP, is a very necessary thing.

The LBP scheme is very simple, since I will use.

Characteristics

The main characteristics of the module:- Input voltage 5 - 40 Volts;

- Output voltage 1.2 - 35 Volts;

- Output current (max) 9 Amps, it is desirable to install a cooler.

Power Supply Diagram

As already mentioned, the scheme is simple. Mains voltage is supplied to the transformer. There is a power switch and a fuse. The voltage is reduced by a transformer. The upper part of the circuit is power. An alternating voltage is supplied to the diode bridge and the smoothing capacitor. Then it goes to the DC-DC converter. From the converter, voltage is supplied to the output terminals. The minus of the circuit is broken by a device. For convenience, the control resistors are removed from the board.The lower one is designed to power the voltammeter. The transformer has a separate winding. As with the power winding, alternating voltage is supplied to the diode bridge and the filter capacitor. Next, I installed a linear stabilizer at 5 volts.

Components

Understood the scheme. Now let's move on to the components.The LBP case will be the old case from the soldering iron regulator. Soldering iron regulator from the times of the USSR. Very kind.

The front panel will be made of composite plastic. The plastic consists of two plates of aluminum and plastic between it. It is white on one side and black on the other. The black side will be front.

Step-down transformer from old equipment, I don’t remember which one. It had to be slightly modified. I made a tap for 22 Volts, a full winding for 27 Volts. If left, then after the diode bridge the voltage is more than 30 volts. This is a lot for a 7805 stabilizer installed on a DC-DC converter. It powers the operational amplifier of the circuit. Although 40 Volts are declared, taking into account the maximum for 7805 at 30 Volts.

.

. For a more accurate display of the output parameters, you need to apply on the 4th segment. I had what was, and applied it.

Clamps of the times of the USSR. Strong and reliable.

Capacitor for 4700 microfarads * 63 Volts. Based on 1000 microfarads per 1 ampere. Another 2 * 470 microfarads are installed on the module.

The diode bridge can be taken as a single one, but I still have it from an old project. Assembled on 4 diodes D242.

Manufacturing

At the bottom of the case, we mark, drill holes for: a transformer, a diode bridge, a module. We solder everything according to the schemes. I soldered two trimmers from the module. Soldered the wires instead. 3 wires for current, 2 wires for voltage.

I will feed the Voltammeter through a 5 Volt linear stabilizer. Diode bridge KTs402 and a small capacitor.

On the back panel I make markings for the network connector and fuse. Everything is neatly cut and installed.

On the front panel I mark and cut out all the holes. There will be: output terminals, power switch, current and voltage resistors, Voltammeter.

Soldered all the elements installed from the inside. The network switch switches both network wires. Initially wanted to use another.

We install all the elements of the front panel. The positive terminal is marked with red paint. Resistor handles in different colors. Red for display color Volt. yellow for current. So far, I have not signed where the current and voltage are. Later I will change the resistors to multi-turn ones, I may also change the handles.

Painted the top cover. There was too much gap between the front panel and the lid, it was covered with a small corner. When checking, the unit gave out 9 amperes in a short, at 28 volts, which amounted to a little more than 250 watts.

Such is the Laboratory Power Supply turned out. They can both power various kinds of devices, as well as charge batteries. Initially, I wanted to use a 24-volt pulse source, but I got a transformer of the required dimensions. Also, I try to collect the device from what is. Thank you all for your attention!

When designing this power supply, the main goal was to be as portable as possible, and if necessary, you could take with you.

I also have other self-made LBPs, but they are only suitable for stationary use.

. This time I decided to use the LM2596 instead of the commonly used LM317 or LM350, to regulate the current.

The beauty of this device is that you can connect it to any 7.5V to 28V DC source. I am using a 19 volt laptop power supply.. The output voltage will be very close to the input voltage, about half a volt less. It can also be used as an unpowered voltmeter, from 2.5V to 30V and as an ammeter . You can also charge the battery with this device, but be careful and watch the current!

Now a little about the assembly of this portable universal LBP

Step 1: Chinese modules and tool:

The basis of all this will be loweringmodule CC-CV LED DC-DC LM2596http://ali.pub/1z01w2

Ammeter with built-in 10 A shunt http://ali.pub/1z029v

Voltmeter (there are different color options for numbers) http://ali.pub/1z02fi

BNS connector + probes http://ali.pub/1z030b http://ali.pub/1z030w

Potentiometers 2 pieces with handles http://ali.pub/1z037p

The rest can be bought at any radio store:

Compact case, can be made of plastic, power input connector, switch, 3 LEDs - different colors.

Tools:

Drill and knife (file)

hot glue

soldering iron

Drills and drills (6mm, 7mm, 10mm)

This simple scheme, it is worth redoing it a little constructively.

The first thing you need to do is to solder the multi-turn tuning resistors - 2 extreme ones and solder the terminals (or solder the taps from our potentiometers, which will be mounted on the case, for ease of control)

Also, if you do not have a transparent case, you need to bring the LEDs to the front panel of the case. For mounting, it is more convenient to take 3mm or 5mm LEDs.

When charging the batteries, the green LED lights up if the current is less than 0.1 of the set current. This parameter can be adjusted using the middle multi-turn resistor left on the board. This is really not necessary, since you already have a built-in digital milliammeter, and you can see how much current the battery is charging.

This circuit is designed for "3A" but not more (critical load current \u003d 3 A). I recommend adding a radiator to the microcircuit, then the current can be supplied up to 3 A not for a short time.

After adding the radiator, I calmly fed the devices with a current of up to 3 A, the radiator heated up, but not critically.

Secured the radiator with a tie.

This is how the modification of the compact-portable universal LBP \ Power supply turned out.

Subscribe to Geek channels:

★ My Aliexpress affiliate ★

★ Get 10.5% off any purchase on Aliexpress! ★

★ Useful browser app for cashback ★

Today I'm going to show you how I build a simple Tesla coil! You may have seen such a coil in some magic show or TV movie. If we ignore the mystical component around the Tesla coil, it's just a high voltage resonant transformer that works without a core. So, in order not to get bored from the jump in theory, let's move on to practice.

Fingerprint sensor and Arduino

Optical fingerprint sensors are commonly used in security systems. These sensors include a DSP chip that processes the image and performs the necessary calculations to find a match between recorded and live data. Inexpensive fingerprint sensors allow you to record up to 162 different fingerprints!

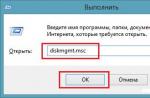

I propose a variant of the device that automatically restarts the computer when it freezes.

It is based on the well-known Arduino board with a minimum number of external electronic components. We connect the transistor to the board according to the figure below. We connect the transistor collector instead of the "Reset" button of the computer to the motherboard, to the contact thatNOT connected to GND

In this video, I will tell you how to make a budget IR station (bottom heating) with heat control for BHA reballing, desoldering and sealing parts. I will show its capabilities and conduct tests. Yes, yes, a conventional ceramic heater emits an IR spectrum

Rather high parameters are declared, and the cost of the finished module is less than the cost of the parts included in it. The small size of the board is tempting.

I decided to purchase a few pieces and try them out. I hope my experience will be useful to not very experienced radio amateurs.

I bought LM2596 modules on Aliexpress, as in the photo above. Although the site showed solid capacitors for 50V, the capacitors are ordinary, and half of the modules with capacitors for 16V.

It's hard to call it a stabilizer...

You might think that it is enough to take a transformer, a diode bridge, connect a module to them, and we have a stabilizer with an output voltage of 3 ... 30 V and a current of up to 2 A (for a short time up to 3 A).That's exactly what I did. Everything was fine with no load. A transformer with two windings of 18 V each and a promised current of up to 1.5 A (the wire was clearly thin by eye, as it turned out).

I needed a +-18 V stabilizer and I set the desired voltage.

With a load of 12 ohms, the current is 1.5 A, here is the waveform, 5 V / cell vertically.

It's hard to call it a stabilizer.

The reason is simple and clear: the capacitor on the board is 200 uF, it serves only for the normal operation of the DC-DC converter. When voltage was applied to the input from a laboratory power supply, everything was fine. The solution is obvious: it is necessary to power the stabilizer from a source with low ripples, that is, add a capacitance after the bridge.

Fighting ripples

Here is the voltage at a load of 1.5 A at the input of the module without an additional capacitor.Increased input capacitance

With the additional 4700uF capacitor at the input, the output ripple was drastically reduced, but at 1.5A it was still noticeable. When the output voltage is reduced to 16V, the ideal straight line (2V/cell).

The voltage drop across the DC-DC module must be at least 2…2.5 V.

Now you can watch the ripple at the output of the pulse converter.

Small ripples with a frequency of 100 Hz modulated with a frequency of several tens of kHz are visible.

Output LC filter

The datasheet on the LM2596 recommends an optional LC output filter. So we'll do it. As a core, I used a cylindrical core from a faulty computer power supply and wound the winding in two layers with 0.8 mm wire.

The red color on the board shows the place for installing the jumper - the common wire of the two channels, the arrow shows the place for soldering the common wire if you do not use the terminals.

Let's see what happened to the RF pulsations.

They are no more. There were small ripples with a frequency of 100 Hz.

Imperfect, but good.

I note that with an increase in the output voltage, the inductor in the module starts to rattle and the RF noise sharply increases at the output, if the voltage is slightly reduced (all this at a load of 12 ohms), the interference and noise completely disappear.

The final scheme of switching on the LM2596 modules

The scheme is simple and obvious.With a long-term load with a current of 1 A, the parts noticeably heat up: the diode bridge, the microcircuit, the module inductor, most of all the inductor (additional inductors are cold). Heating to the touch 50 degrees.

When operating from a laboratory power supply, heating at currents of 1.5 and 2 A is tolerable for several minutes. For long-term operation with high currents, a heat sink to the microcircuit and a larger inductor are desirable.

Mounting

To mount the module, I used self-made "racks" made of tinned wire with a diameter of 1 mm.

This provided convenient mounting and cooling of the modules. Racks can be very hot when soldering, they will not move, unlike simple pins. The same design is convenient if you need to solder external wires to the board - good rigidity and contact.

The board makes it easy to replace the DC-DC module if necessary.

General view of the board with chokes from halves of some kind of ferrite core (inductance is not critical).

Despite the tiny dimensions of the DC-DC module, the overall dimensions of the board turned out to be commensurate with the analog regulator board.

conclusions

1. A transformer with a high-current secondary winding or with a voltage margin is required, in which case the load current may exceed the current of the transformer winding.2. At currents of the order of 2 A and more, a small heat sink to the diode bridge and the 2596 microcircuit is desirable.

3. The power capacitor is desirable with a large capacity, this favorably affects the operation of the stabilizer. Even a large and high-quality container heats up a little, therefore a low ESR is desirable.

4. To suppress ripple with the conversion frequency, an LC output filter is needed.

5. This stabilizer has a clear advantage over conventional compensation in that it can operate in a wide range of output voltages, at low voltages you can get more current at the output than the transformer can provide.

6. Modules allow you to make a power supply with good parameters simply and quickly, bypassing the pitfalls of making boards for pulsed devices, that is, they are good for beginner radio amateurs.

I have already done a couple of reviews of a similar thing (see photo). I ordered those devices not for myself, for friends. A handy device for homemade charging, and not only. I also envied and decided to order already for myself. I ordered not only a voltammeter, but also the cheapest voltmeter. I decided to assemble a power supply for my homemade products. Which of them to put was determined only after I assembled the product completely. Surely there will be people who are interested.

Ordered November 11th. There was a small discount. Even though the price is low.

The parcel went for more than two months. The seller gave the left track from Wedo Express. But still the package arrived and everything works. Formally, there are no complaints.

Since it was this device that I decided to implant in my power supply, I’ll tell you a little more about it.

The device came in a standard plastic bag, “bubbled” from the inside.

The item is currently unavailable. But this is not critical. Ali now has a lot of offers from sellers with a good rating. Moreover, the price is steadily decreasing.

The device was additionally sealed in an antistatic bag.

Inside the actual device and wires with connectors.

Key connectors. On the contrary, do not insert.

The sizes are just tiny.

We look at what is written on the seller's page.

My translation with corrections:

- Measured voltage: 0-100V

- Circuit supply voltage: 4.5-30V

- Minimum resolution (V): 0.01V

- Consumption current: 15mA

- Measured current: 0.03-10A

- Minimum resolution (A): 0.01A

Everything is the same, but very briefly, on the side of the product.

I immediately took it apart and noticed that minor details were missing.

But in the previous modules, this place was occupied by a capacitor.

But their price was also different.

All modules look like twin brothers. Connection experience is also available. The small connector is designed to power the circuit. By the way, at a voltage below 4V, the blue indicator becomes almost invisible. Therefore, we follow the technical characteristics of the device, we do not supply less than 4.5V. If you want to use this device to measure voltages below 4V, you need to power the circuit from a separate source through a "connector with thin wires."

The current consumption of the device is 15mA (when powered by 9V "crown").

Connector with three thick wires - measuring.

There are two accuracy controls (IR and VR). Everything is clear in the photo. Resistors are dark. Therefore, I do not recommend twisting it often (you will break it). The red wires are the leads for voltage, the blue ones are for current, the black ones are “common” (connected to each other). The colors of the wires correspond to the color of the glow of the indicator, do not get confused.

The head chip is unnamed. It once was, but it was destroyed.

And now I will check the accuracy of the readings using the exemplary installation P320. I applied calibrated voltages 2V, 5V, 10V, 12V 20V, 30V to the input. Initially, the device underestimated by one tenth of a volt at certain limits. The error is insignificant. But I adjusted myself.

It can be seen that it shows almost perfectly. Adjusted the right resistor (VR). When the trimmer is rotated clockwise, it adds, when rotated counterclockwise, it decreases the reading.

Now I'll see how it measures the current strength. I power the circuit from 9V (separately) and supply an exemplary current from the P321 installation

The minimum threshold from which it starts to correctly measure the current is 30mA.

As you can see, the current measures quite accurately, so I won’t turn the adjusting resistor. The device measures correctly even at currents greater than 10A, but the shunt starts to heat up. Most likely, the current limit is for this reason.

At a current of 10A, I also do not recommend driving for a long time.

More detailed calibration results are summarized in a table.

I liked the instrument. But there are shortcomings.

1. The inscriptions V and A are painted, so they will not be visible in the dark.

2. The instrument measures current in one direction only.

I would like to draw attention to the fact that it would seem that the same devices, but from different sellers, can be fundamentally different from each other. Be careful.

On their pages, sellers often publish incorrect connection diagrams. In this case, there are no complaints. That's just a little of it (scheme) changed to a more understandable eye.

With this device, in my opinion, everything is clear. Now I'll tell you about the second device, about the voltmeter.

I ordered on the same day, but from a different seller:

Bought for US $1.19. Even with today's exchange rate - funny money. Since in the end I did not install this device, I will go through it briefly. With the same dimensions, the numbers are much larger, which is natural.

This device does not have a single tuning element. Therefore, you can only use it in the form in which it was sent. Let's hope for Chinese good faith. But I'll check.

The installation is the same P320.

More details in the form of a table.

Although this voltmeter turned out to be several times cheaper than a voltammeter, its functionality did not suit me. It does not measure current. And the supply voltage is combined with the measuring circuits. Therefore, it does not measure below 2.6V.

Both devices are exactly the same size. Therefore, replacing one with another in your homemade product is a matter of minutes.

I decided to assemble the power supply on a more universal voltammeter. The devices are inexpensive. There is no burden on the budget. The voltmeter is still in stock. The main thing is that the device is good, and there will always be an application. Just from the store and got the missing components for the power supply.

I have been idle for several years now with such a set of homemade.

The scheme is simple but reliable.

It is pointless to check the completeness, a lot of time has passed, it is too late to make claims. But everything seems to be in place.

The trimmer resistor (complete) is too dumb. I see no point in using it. Everything else will fit.

I know all the disadvantages of linear stabilizers. I have neither the time, nor the desire, nor the opportunity to fence something more worthy. If you need a more powerful power supply with high efficiency, then I'll think about it. Until then, what has been done.

First I soldered the stabilizer board.

I found a suitable case at work.

I rewound the secondary of the torroidal trance to 25V.

Picked up a powerful radiator for the transistor. All this stuffed into the body.

But one of the most important elements of the circuit is the variable resistor. I took a multi-turn type SP5-39B. The output voltage accuracy is the highest.

Here's what happened.

A little unsightly, but the main task is completed. I protected all electrical parts from myself, I also protected myself from electrical parts :)

It remains to "retouch" a little. I will paint the case from a spray can and make the front panel more attractive.

That's all. Good luck!