Sooner or later, every printer owner is faced with the problem of printing distortions. This may be a fuzzy image, darkening of the background, dots, horizontal or vertical stripes. Sometimes the streaks can be barely noticeable, which does not affect the perception of the text, but sometimes they can significantly degrade print quality. It is especially annoying when such streaks occur when printing important documents or advertising leaflets, which simply must look presentable. So what should you do if your printer starts printing with streaks?

Determining the cause of the malfunction

First thing It is recommended to determine the cause There can be several types of printer behavior, although they differ for inkjet and laser printers. Generally speaking, this problem is even more typical for inkjet printers, and it doesn’t really matter, whether it’s an outdated version with cartridges or some modern Epson model equipped with a seven-color CISS (continuous ink supply system) - streaks are unlikely to be avoided. Unfortunately, owners of laser printers may also encounter distortions when printing when the toner runs out or mechanical damage to the cartridge occurs.

Many causes of streaking and other distortions in printing can be determined by their appearance.

Possible reasons, along which an inkjet printer can “strip”:

- poor ink flow (white or multi-colored streaks),

- the nozzles are clogged,

- print head calibration (vertical line breaks),

- encoder disk contamination (white stripes located equidistant from each other).

Possible reasons why a laser printer may streak:

- toner low (white vertical stripes that widen with each new page),

- mechanical damage (vertical stripes of different widths),

- overfilling of the toner waste bin (black dots and specks),

- wear or damage to the image drum (intermittent black stripe along the edge of the page or black dots randomly scattered across the page),

- Problems with the dosing blade (dark streaks on the page or faint vertical streaks).

How to fix an inkjet printer

Poor ink supply

At first glance, it is quite difficult to determine why an inkjet printer suddenly began to produce stripes when printing. However, the most likely option is problem with ink tanks. The first step is to stop printing and refill the cartridges. If it was really a problem of poor ink supply, this method should restore functionality to any printer with RPC (refillable cartridges).

At first glance, it is quite difficult to determine why an inkjet printer suddenly began to produce stripes when printing. However, the most likely option is problem with ink tanks. The first step is to stop printing and refill the cartridges. If it was really a problem of poor ink supply, this method should restore functionality to any printer with RPC (refillable cartridges).

In devices with CISS, poor ink supply can also occur due to air trapped in the loops. Air, in turn, may end up in the plumes in the following cases:

- the system is not sealed,

- filling of donor containers was missed,

- During initial filling, air was not completely removed from the system,

- The containers were lowered below the required level, and air was sucked through the print head.

Air getting into the loops- a common cause of streaks on print when working with Epson printers, as well as some HP and Canon models. It is not difficult to remove air from the loops yourself using a syringe without a needle. Below are instructions for Canon and HP printers with cartridges containing refill inside, as well as for Epson printers.

Algorithm for pumping air out of cables for Canon and HP printers

The instructions are suitable for Canon and HP printers whose cartridges have bleeder holes

Algorithm for pumping air out of cables for Epson printers

- Close the large and small openings of the donor containers.

- Move the carriage to the cartridge replacement position.

- Remove the cartridges from the printer and place them on a piece of paper so as not to stain the work surface.

- Lift the cartridges above the donor containers and open the bleeding hole.

- Insert the syringe into the hole in the cartridge and open the corresponding air hole on the donor container.

- Remove air from the loop using a syringe. In this case, the syringe will contain a certain amount of ink, which can later be poured into donor containers or disposed of.

- Lower the cartridges to the level of the donor containers and close the previously opened air hole on one of them.

- Remove the syringe from the cartridge and close the hole with the stopper.

- Install the cartridges into the printer and place the remote containers at the desired level. Open the air holes of the donor containers.

Nozzles clogged

The next step is to check the nozzles. To do this, you need to print a test page. If there are gaps on the page, you can actually talk about clogged nozzles. In this case, to fix the problem, you need to clean them programmatically.

Software method for cleaning nozzles

After cleaning is completed, you need to do a nozzle test. If the test image does not contain gaps, this means that head is clean. If the gaps do not disappear, you need to do a simple cleaning of the nozzles two more times. If there is no result, intensive cleaning is performed.

Print head calibration

If the previous steps did not produce results, then perhaps the problem is that the print head has miscalibrated. The reason for this may be that the printer carriage has shifted during transportation. The solution to the problem is quite simple: you can calibrate the head in the service program in the “Service” tab.

Encoder disk dirty

Finally, distortion during printing can be caused by contamination of the encoder tape and disk, which is manifested by the presence of white horizontal stripes located equidistant from each other. The stripes may vary in width - it depends on how dirty the disk is.

Encoder disk- a transparent circle with markings applied to it - is located on the far left side of the printer. If the markings are covered with dust and dried ink, this will lead to incorrect paper positioning. To get rid of dirt, you should wipe the disk with a soft cloth (toilet paper, lint-free cloth) moistened with a liquid that contains alcohol - this can be a window cleaner or a special liquid for washing cartridges.

Attention! Do not use acetone to clean the encoder disk as it can easily remove the markings.

It is also necessary to wipe the encoder tape, which is responsible for positioning the carriage. It is usually located directly above the shaft along which the carriage moves. The tape should be cleaned carefully so that it does not come off the fastenings, otherwise you will have to contact a specialist to disassemble the device.

Out of toner

In most cases, a laser printer prints in stripes due to the condition of the cartridge. If, when printing, vertical white stripes form on the pages, which become wider each time, then there can be one reason - the toner has run out, which means you just need to refill the cartridge.

In most cases, a laser printer prints in stripes due to the condition of the cartridge. If, when printing, vertical white stripes form on the pages, which become wider each time, then there can be one reason - the toner has run out, which means you just need to refill the cartridge.

Attention! Do not shake the cartridge if you are out of toner. In this case, waste may fall out of the hopper, printing with which will significantly shorten the life of the cartridge.

Other reasons

Running out of toner is the only case when a printer that prints in stripes can be “fixed” yourself. In other cases, which will be discussed below, you must contact the service center. It is recommended to take a test page with you: by the dots and stripes on it, an experienced technician will immediately understand what kind of problems he will have to work with.

Drum unit is worn or damaged

If, when printing, an uneven black line appears on one edge of the page, this is a sure sign of wear on the photoconductor - the edges of the paper are erasing a layer of photosensitive varnish. The varnish can also be erased by various metal objects encountered during printing - paper clips and staples. In this case, black dots appear on the printed copy, located, at first glance, chaotically. However, if you look closely, you will notice that the pattern formed by the dots is repeated several times on the sheet.

Further use of the printer may further deteriorate the condition of the photoconductor and squeegee - the cleaning blade. It is necessary to contact a specialist as soon as possible.

Problems with the metering blade

There are two possible problems with the metering blade: it is not installed correctly or it becomes dirty during use of the printer. If the dispensing blade is not installed correctly, it will leak more toner than is required for printing, resulting in dark streaks on the page. If the blade becomes dirty, it, on the contrary, begins to let through less toner. In this case, faint or even white (if heavily soiled) vertical stripes appear on printed copies.

There are two possible problems with the metering blade: it is not installed correctly or it becomes dirty during use of the printer. If the dispensing blade is not installed correctly, it will leak more toner than is required for printing, resulting in dark streaks on the page. If the blade becomes dirty, it, on the contrary, begins to let through less toner. In this case, faint or even white (if heavily soiled) vertical stripes appear on printed copies.

If the cartridge is mechanically damaged and the waste bin is overfilled, it is also recommended to contact a service center.

Conclusion

Very often printer owners Epson, Canon, HP and other popular brands are wondering why the device suddenly began to produce stripes and various lines when printing. This problem can signal a variety of problems, some of which can be easily fixed on your own, while others require a trip to a service center. The most common problem with HP laser printers is running out of toner, while Epson inkjet models are characterized by air getting into the loops through which the ink flows. More serious problems, such as mechanical damage to printer parts, require the attention of a specialist.

The most common printing defect in printer operation is the appearance of streaks on the paper. They can be narrow, wide, horizontal or vertical, more blurry or very bright, colored or monochrome, with or without spaces. In this case, any stripes do not stain the printed document at all. After all, this is a serious defect, which is not always easy to get rid of. So let's find out why streaks appear on paper when printing and find out how to fix this problem.

There are several typical reasons that lead to the formation of streaks on paper. However, they are different for inkjet and laser printers. First, let's talk about why an inkjet printer can streak:

- Ink is running out.

- The ink has dried out or thickened inside the print head (usually because the device has not been used for a long time).

- The integrity and tightness of the cartridge is broken.

- Shaft deformation has occurred (often associated with the long service life of the device).

- The print head is faulty. She may be airy. Either the cable itself is faulty/pinched. Most often, with such a breakdown, horizontal stripes are observed on the sheet.

- The esconder elements are dirty or damaged. This is the tape itself or the sensor.

These are the most common reasons. However, streaks during printing may also appear as a result of other faults that are not listed above.

Troubleshooting algorithm for inkjet printer

We figured out why the printer prints in stripes. Now let's talk about how to diagnose and eliminate all the faults listed above, which are often the reasons for the appearance of streaks on paper. To make it easier for you, we recommend following the following algorithm:

- Insert clean paper into the printer tray.

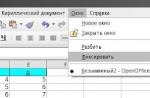

- Open the management utility or go to the specialized device settings center.

- Find the “Service” or “Maintenance” section.

- We start cleaning the print head and checking the nozzles.

- If the problem is not solved, then repeat the operation 1-2 more times. Don't forget to wait about 2-3 hours. Then we check whether the printer has stopped printing in stripes.

However, it is not always possible to clean the print head using software. For example, this procedure is pointless on the Canon Pixma MG2440 inkjet MFP. This model does not have a pump for cleaning the print heads. Therefore, you can remove dried ink manually. For example, using chemical cleaning products.

Did cleaning the print head and manually flushing with liquids not help? Then, most likely, this part has failed. Print head failure occurs quite often. The most common reason is careless handling of this mechanism during removal/installation. In addition, if you print a lot on a printer or MFP, then the head failure is simply due to normal wear and tear. Which exit? The answer is obvious - replacement of the part. The easiest way is if it is built into the cartridge. But most printers (for example, Epson) have a separate head, and its price ranges from 50 to 80% of the cost of a new device.

Have you followed the given algorithm, but the inkjet printer continues to streak? This means you should contact a service center for help. Or even seriously consider purchasing a new device.

Why does a laser printer print in stripes?

You can often observe streaks when printing on laser printers. What could be the cause of such a malfunction? The list is quite large:

- Ink levels are low.

- Cartridge depressurization.

- The photoconductor is damaged/destroyed.

- The magnetic shaft is damaged or a foreign object has fallen on it (with such a malfunction, in 80% of cases the sheet comes out of print with a black stripe along the edge or side).

- The hopper is full, where waste toner goes.

- The toner dispensing blade is not securely attached.

- The contact between the photodrum and the magnetic shaft is broken

And this list can be continued for a very long time. But we have named the most common reasons, so let’s move on to how to fix printing failures and finally forget about sheets with stripes.

Getting rid of streaks when printing on a laser printer

When diagnosing problems in the operation of a laser device, we recommend that you pay attention to the specific appearance of stripes. This will help you understand what exactly caused the printing defect.

- Let's say a laser printer prints a stripe in the middle. Typically, this indicates that the toner is running low. Moreover, the less ink in the cartridge, the wider the stripe. If you checked and made sure that there is enough toner, then the supply system is faulty. It is better to contact a service center.

- The stripes consist of small dots. In 90% of cases, such a printing defect is due to the fact that the hopper, which collects toner residues, is full. What should be done in such a situation? Of course, clean the bunker. By the way, it is advisable to carry out this procedure every time you refill the cartridge. Sometimes streaks of small dots also occur because the dosing blade is not installed correctly. So don't forget to check that too.

- Unprinted, white and rather wide stripes on the sheet. There may be several reasons. For example, toner is low. Or a foreign object (a paper clip, a piece of paper or tape, a coin, etc.) has fallen onto the shaft. In this case, getting rid of the stripes is not difficult. It is enough to remove the foreign body.

- Are there faint black stripes across the sheet? This doesn't bode well. This is often caused by wear on the magnetic shaft. The situation can be corrected by replacing the unit or cartridge.

- Dark stripes on one or both edges of the leaf. These indicate wear or damage to the photoconductor. Most likely, you will have to change the part. The fact is that the sensitive layer of the photodrum wears off over time, which, to put it mildly, is problematic to restore.

- Irregularly shaped stripes fill the entire sheet (looks like a background). It is likely that low quality toner was used when refilling the cartridge. Another potential reason for this printing defect is that the magnetic roller or optical system of the printer is dirty.

- Horizontal and almost equidistant stripes from each other. Most often, the problem lies in poor contact between the magnetic shaft and the photodrum. Perhaps the toner has spilled out, the ink waste bin is full, or it may be due to poor quality cartridge refilling. It is recommended to clean the shaft contact and other surfaces. If this does not help, then it makes sense to install a new cartridge.

As you can see, there is nothing complicated. At the same time, eliminating streaks when printing on a laser printer is often easier and faster than on an inkjet printer. If the device produces stripes on printed paper, then you just need to pay attention to their shape and area of appearance, and also check:

- Toner level;

- The health of the photodrum;

- Cartridge condition;

- Position of the dosing blade;

- The fullness of the mining bunker.

- If you clean the print head or nozzles on your printer yourself, never use alcohol or water. It is best to purchase a special cleaning liquid. It is sold in the same stores where printer ink is sold. In extreme cases, you can use glass washing liquid.

- To quickly eliminate streaks when printing on HP and Canon printers, we recommend that you first pay attention to the ink levels, as well as the waste toner tank. Basically, devices of these brands begin to “strip” because of this. Owners of printers and MFPs from Xerox or Samsung do not have to think about cleaning the waste buffer. As a rule, the cartridges of such devices are not equipped with it.

- If your inkjet printer has black and color cartridges full of toner, the nozzle and print head tests are excellent, but stripes still appear when printing, then perhaps the reason lies elsewhere. For example, the head is calibrated. This happens if the device has been transported somewhere, rearranged, or shaken a little, moving the carriage. You need to go to the printer control center and start calibrating the print head.

- To prevent streaking when printing, you should regularly clean the cartridge. Especially if you refill it yourself. The fact is that the ink for refilling is usually non-original (most users do not buy it because of the high cost), which is inferior in quality to the toner from the manufacturer. In particular, they dry out faster and clog the nozzles.

Any printer, whether laser or inkjet, during operation comes to a stage in its operation when the print quality deteriorates. The printed pages become dull, horizontal or vertical stripes appear on the sheet, the image is printed with gaps (no shading in places), etc. All these troubles can appear for various reasons, which depend on the printing technology used in the devices. For a laser printer, these are problems with the cartridge or drum, and for an inkjet printer, if he prints with stripes, there are malfunctions in the print head, interruptions in ink.

There are not so many reasons for the appearance of “striations” on a sheet coming out of the printer.

A manufacturing defect cannot be ruled out, especially if your newly purchased device begins to draw stripes.

But, if before the appearance of this defect your machine printed well, then in most cases the problem can be fixed at home, and you can do without a trip to the service center.

Checking Ink Levels

First of all, you should check the ink levels on your inkjet printer. To determine the ink level, you can use software, namely a utility that comes with any printing equipment. For example, to determine how depleted the cartridge resources are in HP equipment, you need to launch a program designed to control the device and select the “Approximate ink levels” tab. The utility window is shown in the figure below.

For Epson units the window will look like this:

When the ink level in the cartridge reaches zero, it must either be refilled or replaced with a new one.

If to the printer CISS connected, this program will be useless. The ink level is easily determined by looking at the transparent CISS containers. If there is enough ink in them, then you should check the cable through which the ink enters the cartridges. It should not contain kinks, the cable tubes should not be pinched by anything, and there should be no air pockets (small areas with air) in them. You should also check the air filters on the CISS tanks. If they are clogged with dust or paint, then there will be no air leaks into the container, and the ink from these containers will stop flowing to the print head, which will cause streaks to appear during printing.

Cleaning the print head

For inkjet printers, it is very important that there is no downtime. Otherwise, due to a long pause, the ink in the print head dries out and clogs the nozzles - the holes through which ink is sprayed onto the paper.

In some models of printing equipment, the print head can dry out within a couple of days of equipment downtime.

But for most devices, it takes 1 to 3 weeks for the ink to dry in the nozzles. In any case, you need to turn on the device regularly so that it can “blow through” the nozzles with ink.

In modern printers and MFPs, the manufacturer has provided the ability to clean the print head using the device itself, with using a proprietary utility. For example, for an HP device this function is called “Cleaning cartridges”.

For Epson printers, this function is called “Print Head Cleaning”. This software also allows you to do a preliminary check, which allows you to determine from the printed impression whether the nozzles are actually clogged. This function is useful for saving ink, since when cleaning the print head there is an increased consumption of ink: it is the ink that washes the nozzles.

For Canon devices, to clean the head, in the utility window you need to click on the “Cleaning” item, or “Deep cleaning” - a more advanced type of it, with a high consumption of ink.

If the inkjet printer prints in stripes, it is recommended to repeat this procedure 2-3 times in a row, and let the device “settle” for a couple of hours, after which it can be used for its intended purpose.

If hardware cleaning does not help, you will have to resort to manual washing of the print head as shown in this video.

If the inkjet head is built into a cartridge, it is recommended to soak the nozzles in Mr. Muscle glass cleaner for at least a day. It is desirable that the liquid be green or blue. The nozzles should be soaked in such a way that the detergent does not come into contact with the electrical contacts. After soaking, carefully blot the nozzles with a napkin, insert the cartridge into the printer, and run the standard cleaning procedure described above.

It is not recommended to soak and wash the inkjet head from an Epson printer at home, since it is very “capricious” and can easily be rendered unusable. The price of a new head is comparable to the price of a new printer. Therefore, if you suspect that the nozzles have dried out, it is better to contact a service center.

Problems with encoder strip and disk

Also, the reason that a white stripe appears when printing, which is repeated at the same distance, may be the presence clogs on the encoder disk. It is usually located on the left side of the unit on the paper feed shaft. The disc is made of transparent plastic and has special markings.

When there is dust, paint or other contaminants on the disk markings, the optocoupler sensors are not able to correctly read the information, and the paper is positioned incorrectly. You can also use Mr. Muscle to clean the disc. It is important that this product is intended for cleaning glass and contains ammonia.

The carriage into which the cartridges are inserted is positioned along the encoder tape. It is a transparent strip of plastic with strokes applied to it. It is located near the back wall (inside the device).

If dirt gets on the tape, then the correct carriage positioning gets lost, and the text or image when printed is shifted to the side at regular intervals. Wipe this tape with the same product as the encoder disk. Just be careful during this procedure. If the tape comes off the fasteners, you will have to disassemble half of the device to put it back in place.

Important! Acetone and other solvents should not be used to clean the encoder disk or tape, as this can erase the markings.

Why does a laser printer print in stripes?

Before looking for the reason why a laser printing machine streaks, it is necessary to have at least a minimal understanding of the structure of the unit. It can be clearly seen in the following figure.

When printing on a laser printer, the appearance of streaks can be caused by the following reasons:

- damage to the photodrum;

- broken contacts between the magnetic shaft and the photodrum;

- toner has run out;

- damage to the magnetic shaft;

- cartridge leakage;

- Waste bin overflowing.

Drum damage

The photodrum is an aluminum shaft that has a special coating that is sensitive to optical radiation. Only the outer layer is sensitive to laser radiation, which becomes thinner over time and wears off in some places.

Even if wear is not visually detected, thinning of the active layer still affects print quality. In this case, along the edges of the sheet black stripes appear. As the active layer on the image drum wears, the stripes will expand.

It should be noted that toner consumption in these areas will be higher because the thickness of the toner layer on the drum will be high. As a result, other parts of the cartridge or the printer itself, for example, the thermal unit, may fail.

Although there is a method for restoring the active layer on the photodrum, it is not very effective. The best way out of this situation is to replace the part with a new one.

Lost contact between the magnetic roller and the photodrum

If a sheet comes out of the printer with horizontal stripes located at the same distance relative to each other, this is a sign of poor contact between the photodrum and the magnetic shaft.

Such a nuisance arises when the toner spills or the waste bin overflows. This defect may also occur after improper cartridge refilling or wear of the shaft, squeegee, photodrum. The problem is solved by replacing failed components or refilling the cartridge with high quality.

Out of toner

You can tell that the cartridge is running out of toner if marks appear on the sheet. white stripes having different widths.

What should I do if I run out of toner? The answer is obvious: replace or refill the cartridge.

Damage to the magnetic shaft

The main purpose of the magnetic roller is to transfer toner to the photodrum. Since the toner has abrasive particles, it is because of them that the magnetic roller wears out.

If the magnetic shaft is damaged, the following printing defects become noticeable:

- white voids appear on the sheet;

- gray blots appear, evenly spaced on the paper;

- pale print;

- uneven filling of the image.

Also, if the magnetic shaft is damaged, horizontal wavy stripes.

This problem can only be solved by replacing the shaft.

Cartridge leaks

This indicates that the seal of the cartridge is broken. vertical stripes, located chaotically, and each time in a new place.

You need to remove the cartridge from the device and check whether toner is spilling out of it. If this is the case, then you should check this element for mechanical damage, whether the rubber seals are inserted well to prevent the toner from spilling out. If cracks or other irreparable damage is detected, the cartridge must be replaced.

Waste bin is full

The cartridge contains a squeegee that removes unused toner. The latter is disposed of in a special container called a waste bin. This compartment is usually cleared when replacing cartridge. If the hopper is not cleaned, it will become overfilled with toner, which will spill out. The following figure shows the effect caused by overfilling the waste compartment.

By the way, such a black stripe appears if the squeegee (the blade that cleans the drum) is worn out, deformed, or a foreign object, such as a paper clip, has gotten under it.

The squeegee looks like the picture below.

To get rid of the printing defect, you will need to clean the waste bin or replace the blade.

Over time, the printer begins to perform worse and this is noticeable in the print quality. The appearance of various defects and various stripes indicates wear and tear on the printer parts. Instead of the usual letters, you see stripes of varying widths. They can be one color or multi-colored, located horizontally or vertically, in one or several places on the sheet.

There are many reasons for poor quality printing, but the most common are wear of parts and clogging of the printing hammer with paint. Next, we will look at both the causes and ways to eliminate them.

If you have an inkjet printer

“Striped” printing in inkjet printers from any manufacturer appears for the following reasons:- When the ink runs out, the chip either blocks the cartridge or, as in HP printers, prints poorly, with streaks.

- The print head, the device that applies the ink, is clogged with dried particles.

- There is air in the print head.

- There is a malfunction in the printing mechanism (loop cable, for example).

Troubleshooting

Step oneCheck how much ink is left:

And this is what a printer from Epson will show (picture above).

And if your printer has a CISS system, a device that supplies the print head with ink from refillable cans, then the utility is not needed. The reservoirs show how much ink is left.

If the problem is that there is not enough ink, simply refill or replace the cartridge.

Step two

The print head may become clogged, in which case it needs to be cleaned. If your device is from Epson, you will find the print head in the printer. And if from HP and Canon, look in the cartridge. To solve the problem in this case, just install another cartridge. But if you don’t want to change it because there is still ink, or buying a print head, for example, in Epson printers will be too expensive, you can try cleaning it. Moreover, it is better to do this using software methods. So:

- Check if there is paper in the printer and in the control program, for example, Head Cleaning, find the “Service” or “Maintenance” tab.

- The program will clean the printing hammer, and you can check how ink flows from the nozzles or nozzles using the Nozzle Check utility.

HP

Canon

If the problem persists, run the print head cleaning and nozzle check one or two more times. Does not work? Call Mr. Muscle to your home and use his surface cleaner. The chemicals it contains can dissolve dried ink from the print head.

If your printer model produces ink continuously, make sure the holes are clean. The ink may not be able to enter the print head due to lack of air. This happens if there is a filter. It can become dirty and prevent air from flowing freely. Change the filters or remove them completely.

The problem of “strip” printing often occurs when the printer is used occasionally. Make it a habit to run your printer every few days as a preventative measure to keep the ink from drying out. In this case, printing is optional. As soon as you turn on the device, the nozzles release a small amount of ink, enough to not dry out for several days.

Have you changed the ink cartridge or refilled it and the printer stopped printing? It is possible that air has entered the print head and in this case it needs to be cleaned.

Perhaps the print head is faulty? You cleaned it using both software methods and Mr. Muscle, but the problem remained. In this case, it is not a matter of contamination, but a breakdown. The head itself, its parts or the cable may fail.

This problem is common among those users whose printer is actively used every day. The ink supply device may have become unusable due to frequent removal. The problem can only be solved by purchasing a printing mechanism or parts for it. And this is a minus of the Epson inkjet printer, since the part can cost as much as the device itself.

And with HP or Canon printers, everything is solved simply - by replacing the ink cartridge. This is where the printing mechanism is located in printers from these manufacturers. We replaced the cartridge and the problem was solved. True, this also costs money, but that is another problem.

If the printing mechanism is located in the printer, you will not be able to solve the problem on your own. In this case, it is better to contact an office equipment repair shop.

If a laser printer prints in stripes

The laser printer began to print poorly, which means:- The toner is running low.

- The cartridge allows air to pass through.

- The waste toner bin is full of waste.

- The drum or cartridge part is faulty.

- The toner adjustment blade is not installed correctly.

- The magnetic shaft and photodrum are not in contact.

- The magnetic shaft is damaged, or the reason lies in a foreign object getting into it.

Troubleshoot printing problems in different situations

The stripes appear in different places each time

Streaks everywhere in different places when printing may indicate problems with the toner cartridge. Perhaps it is not hermetically sealed?

If the rubber bands on the toner are loose or torn, the toner will spill out. Also check the body of the toner cartridge; perhaps the problem lies in its external damage. If these cases are confirmed, try to eliminate the defect, and if this does not work, you will have to buy a new cartridge.

The stripes consist of individual small dots

This happens if your cartridge was refilled poorly. The problem could also be in the hopper or the metering blade.

Refill the cartridge again and check all the details that we mentioned just above. If the problem is the blade, reinstall it; if the problem is an overfilled hopper, clean it.

Unprinted stripes in any part of the sheet

If the toner is running out or a piece of it gets on the magnetic roller, this problem occurs. The recommendation is simple - refill the cartridge.

A wavy or intermittent stripe is located along the edges of the sheet on one or both sides

The photodrum, the main part of a laser printer, is an aluminum cylinder that is coated with a photoconductive dielectric. The toner is supplied to the drum using a magnetic roller. If you use the printer for a long time, the photoconductive material will rub off on the paper. The way out in this case is to buy a new photodrum.

Horizontal stripes at equal distances from each other

Spilled toner causes poor contact between the drum and the magnetic roller, or the hopper becomes full of waste. Refill the cartridge properly, replace the cable and the problem will be solved.

Reduced print quality is one of the main problems of any printing equipment, including home and office printers and MFPs. This often manifests itself in the form of various defects on printed sheets of paper. Why can Canon printers start printing in stripes, and how to deal with it?

Causes of stripes

Deterioration in print quality can be caused by many reasons:

- The cartridges are low on ink.

- Clogging of nozzles (nozzles), depressurization and other cartridge malfunctions.

- There is a malfunction or blockage in the toner supply system from the cartridges to the print head.

- The print head is dirty or misaligned.

- Overfilling of the diaper - a device that absorbs unused ink.

- Print head positioning errors due to problems reading the encoder (positioning) tape.

- Hardware malfunctions of functional components of the printer and others.

Let's look at the simplest and at the same time effective ways to eliminate the malfunctions listed above.

Cartridges are running low on ink

If the ink in the cartridges is running low, the printer independently reports this by displaying a corresponding message on the front panel or on the computer monitor. This may not happen for several reasons:

- Malfunctions in the printer control firmware;

- Damage to electronic components of ink tanks;

- Malfunctions of sensors that determine the ink level in cartridges;

- The user can disable the ink level monitoring feature.

The last reason is the most common. Disabling the ink level monitoring function is usually done when replacing or. After this, the printer stops reporting the end of ink in the ink tanks. At the first symptoms of a decrease in print quality, the first thing you need to do is make sure that there is ink in the cartridges, and only then take on other solutions to the problem.

Cartridge malfunctions

There is a long list of cartridge problems that can cause poor print quality and streaking. The most common problems:

- The ink nozzles are clogged with dried ink or foreign small objects.

- Loose installation of cartridges.

- Ink leaks at the outlet of ink tanks due to depressurization of connecting elements.

- Physical damage to nozzles and others.

You can try to fix the first two problems yourself. Any problems due to physical damage will most likely require replacement of the cartridges.

If the nozzles are dirty, the following cleaning procedure can help:

- For “cosmetic” cleaning of the nozzles, you can use a cotton swab moistened with clean water. Dried paint, small particles of dust and other contaminants should be removed from the working surface of the cartridges. To wet the tampon, do not use alcohol-containing solutions, solvents or other aggressive liquids.

- For “general” cleaning of the nozzles, you can try soaking the cartridge in water. To do this, take several napkins, place them in a shallow container and fill them with water so that they are completely immersed in it, but not deeper than 2-3 mm. Place the cartridge with the nozzles down on top of the wipes. Wait 20-30 minutes until the ink begins to flow out of the ink tank.

If the cartridges have not been used for a long time, then cleaning them using these methods may not help. In these cases, it is better to seek help from specialists.

If the cause of ink leaks is loose cartridges, this can be corrected as follows:

- Install the cartridges into the carriage by pushing them until they click into place.

- On top of the inkwells, attach 1 cm thick foam rubber or paper folded several times.

- Close the carriage cover securely.

Ink leaks can also be caused by damage to the carriage itself. If cleaning the cartridges or even replacing them does not help solve the problem, it is better to take the printer to a workshop.

The print head is dirty or misaligned

All of these problems can be resolved by running utility functions on the printer. The corresponding procedures can be launched either using buttons or the touch panel on the printer body, or using the driver installed on the computer. Let's consider the last method.

To clean the print head, follow these steps on your computer:

- Go from the "Control Panel" to the "Devices and Printers" section.

- Right-click on the printer's name, then select "Settings" or "Properties". The printer driver settings window opens.

- Go to the "Maintenance" tab.

- Select Printhead Cleaning, then click the Run button. Follow the instructions on the screen.

- If simple cleaning does not help, run the Deep Clean function. This procedure will require a relatively large amount of ink, but will clean the print head more efficiently.

Modern Canon printer models also provide the ability to clean the entire ink supply system. To run the corresponding function, do the following:

- Select the "System Cleanup" item in the "Maintenance" tab of the driver settings window.

- The program will prompt you to select a group of cartridges on which the cleaning operation will be performed. You can select all suggested groups.

- Next, select "Initial Check Elements". The screen will display the requirements that must be met before starting the system cleanup procedure.

- Click on the "Run" button, then "OK", the cleaning procedure will start.

- If cleaning the ink supply system does not lead to the desired result, the manufacturer recommends turning off the printer for 24 hours, then repeating the procedure.

If the cause of streaks on your printouts is a misaligned print head, you can solve this problem as follows:

- Load several sheets of paper into the printer.

- On your computer, open the Maintenance tab in the printer driver settings window.

- Select Special Options.

- In the new window, switch the checkbox to “Align heads manually,” then click OK.

- The "Maintenance" tab of the driver settings window will re-open. Now select the Printhead Alignment item.

- Click on the "Align Print Head" button in the newly opened window.

- Follow the instructions on the screen.

Diaper overflow

A diaper is an absorbent lining into which, after the next printing cycle, the ink remaining on the surface of the print head flows. In the chamber where the diaper is installed, there is also a sensor that determines the level of filling of the absorbent lining. This sensor can also be disabled by the user. If this has been done previously, the printer will continue to operate despite the diaper overflowing. After some time, the ink will begin to splash out of the camera, which will lead to various printing defects.

The only way out of this situation is replacement or, at a minimum, . In any case, the printer will have to be completely disassembled, because... it is impossible to get to the diaper by other means. If you have tools and some experience in repairing office equipment, you can do this yourself, but it is better to turn to specialists.

Print head positioning errors

To print, the printer needs to determine the current position of the print head in the horizontal plane. This is done using markings applied to the positioning tape (encoder tape). An optical sensor built into the print head determines its position based on the markings and transmits the corresponding information to the printer control board. If the sensor fails to read the tag, it skips it. This causes vertical stripes to appear on printed samples. Moreover, the stripes are expressed in the form of unprinted elements.

Encoder tape contamination is usually caused by ink or large amounts of paper dust, lint, etc. accumulated. In most cases, it is enough to remove the upper part of the printer housing. To clean the tape, you need to use a dampened cotton swab.

Problems with functional printer components

The cause of streaks on printed samples is usually the moving mechanisms of the printer, which are responsible for moving the print head and/or feeding the paper. For example, these could be rubber traction rollers, gears, rotation transmission belts, or even electric motors.

As practice shows, most often a decrease in print quality occurs due to print head malfunctions. In any case, to resolve hardware faults, you should contact a service center, because Repairing such delicate equipment yourself can lead to critical problems.